OPERATIONAL EXCELLENCE

An Organisational Philosophy is similar to the word Human replaced with Organisation. Operations Excellence is all about living up to this Philosophy. An Organisation has to reach a certain level of Maturity to deploy the Operational Excellence Tools.

The Organisational Leadership has to encourage a paradigm shift from the run-of-the-mill work attitude towards Benchmarking Performance in every activity it's Team Members are engaged in. An Organisation has to reach a certain level of Maturity to deploy the Operational Excellence Tools. Over the Years, these Tools have evolved and are well tested for its purpose. However. the challenge lies in the identification of the right Tool and the Right Time for Deployment. Organisations rush to implement on an adhoc basis and loose steam quite early, ending this initiative prematurely or at most painfully drag due to Customer insistence. We help you to put together this Program in an Structured Order for Sustenance and Measurable Success. The Team at Qltc has expertise in conducting Operational Excellence Studies, Select the appropriate Tool, Prepare a Project Charter. Guide the Team Members and arrive at Root Cause with recommended Solutions, Contact us to hear our success Stories.

OUR COURSES

Six Sigma Green belt

Six Sigma Green Belt is a professional certification in the field of data analysis and process improvement. Through the Six Sigma Green Belt training and certification course, the participants will receive an introduction to the tools and techniques used to identify and eliminate defects and wastes.

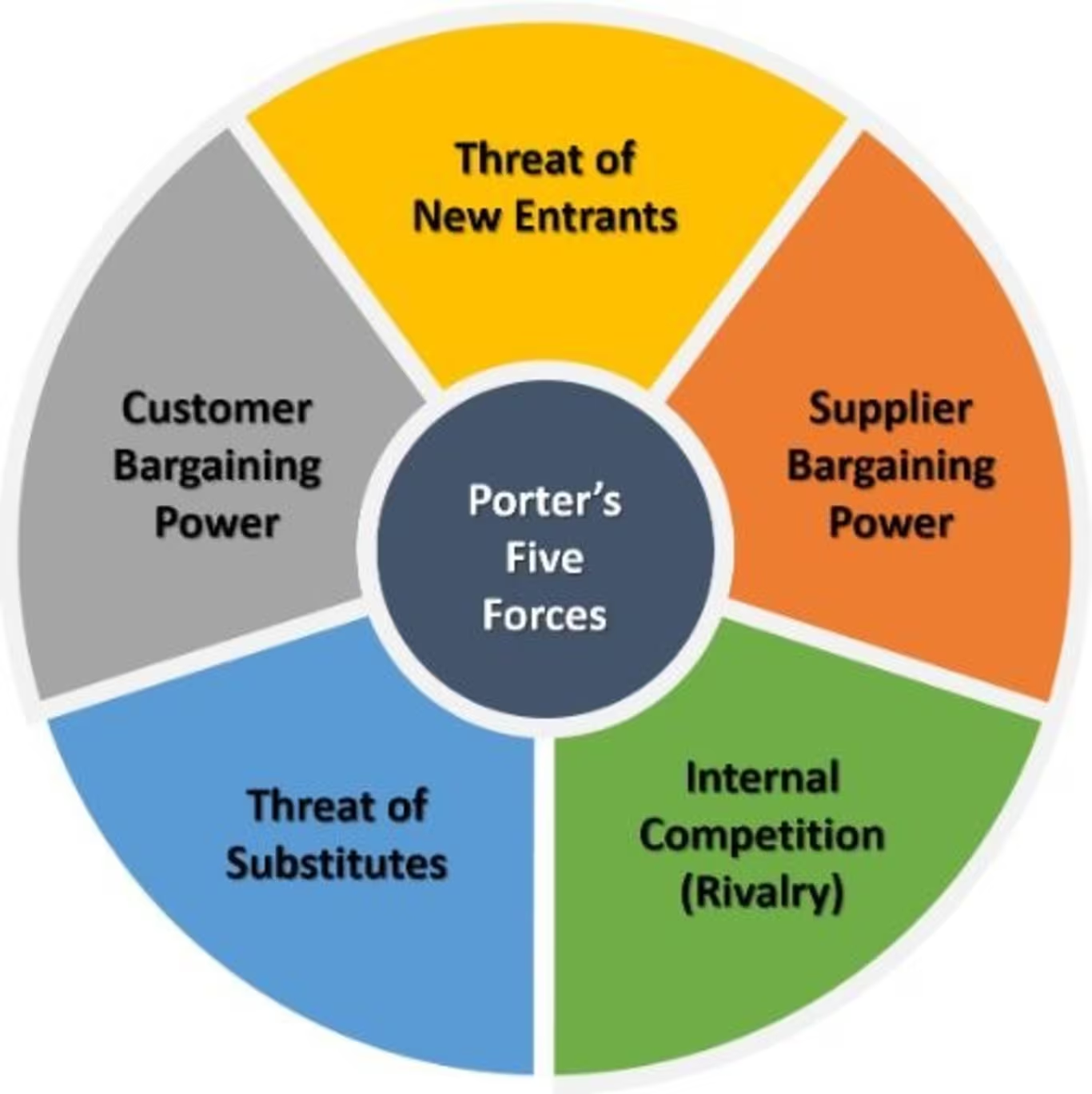

Porter's Five Forces Theory

This framework is a fundamental tool for assessing the competitive dynamics within industries. Participants will gain practical insights into each of the five forces and learn how to apply this knowledge to make strategic decisions and gain a competitive edge.

Failure Mode Effect Analysis (FMEA)

This comprehensive course is designed to equip participants with the essential knowledge and skills to conduct effective Failure Mode and Effect Analysis (FMEA). Hands-on experience in applying FMEA principles, using industry best practices, and developing actionable strategies to enhance reliability and minimise risks.

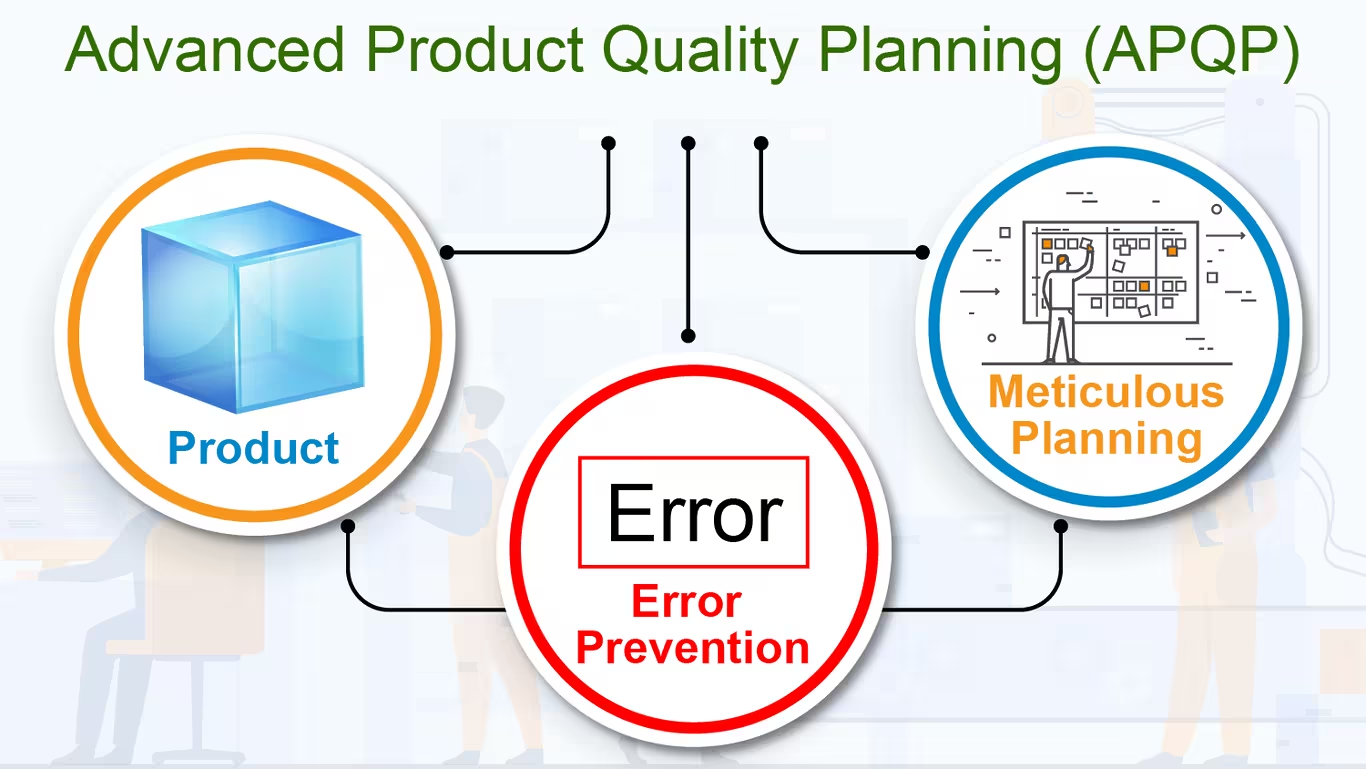

Advanced Product Quality Planning (APQP) and Control Plan

APQP is a critical framework for organisations aiming to achieve high-quality products through effective planning, collaboration, and risk management. This course give insights into the key elements of APQP and learn how to apply them in their respective roles to drive quality and customer satisfaction.

Measurement System Analysis (MSA)

The Measurement System Analysis (MSA) course is designed to equip participants with the knowledge and skills necessary to assess, improve, and ensure the reliability and accuracy of measurement systems within an organisational context.

Production Part Approval Process (PPAP)

PPAP is a critical element in ensuring the quality and consistency of products in various industries, particularly automotive and manufacturing. This course helps in deep understanding of PPAP requirements, documentation, and best practices to successfully navigate the product approval process.

8D - Problem Solving

The 8D methodology aims to identify the root causes of problems and implement effective corrective and preventive actions to prevent recurrence. This course gives practical insights into each discipline of the 8D process, enabling them to lead or contribute to successful problem-solving initiatives within their organisations.

OUR COURSES

- Deploying a Balanced Scorecard

Balanced Scorecard

- ISO IMS Implementer Course

- ISO 9001:2015(QMS)

- ISO 14001:2015(EMS)

- ISO 17020:2012

- ISO 45001:2018(OHSMS)

- ISO 50001:2018(EnMS)

Enterprise Risk Management

- Six Sigma Green Belt

- Porter's 5 Forces Theory

- APQP & Control Plan

- FMEA

- PPAP

- MSA

- 8D - Problem Solving

Operational Excellence

- Empower your Supervisors

- SDP

- Industrial Safety Training

People Development

-

Phone Number

+91-8147135973 -

Email Address

Info@qltc.in -

Street Address

No 578, Sri Durga Arcade, 2nd Floor,Above Axis Bank Ltd,18th Cross, Banashankari 3rd Stage, Bangalore, Karnataka 560085 -

Website URL

www.qltc.in